NATSPEC understands that construction quality is affected by the level of project team integration, and how well groups collaborate within this complex system. Manufacturers are a key part of many groups in a construction project. One challenge in establishing teams is the time required to form trust. NATSPEC can accelerate trust-building through its many products and services, built from its experience with government departments, industry stakeholders and around 1,700 subscribing organisations who together represent leading designers and specifiers.

During project bidding and procurement, sourcing products is a time-intensive activity for specifiers. Specifiers who do not ask for particular products risk paying a high price (read 'Showcase in the National Construction Product Register (NCPR) and Become a Trusted Brand'). NATSPEC is committed to help specifiers identify and specify quality products for construction projects. Specifiers have increasingly reaffirmed that they rely on the NATSPEC Partner Program to find trusted brands.

NATSPEC does all that work for us, and almost certainly does it better. We are delivered a document which is comprehensive, up to date, relevant and incredibly useful. The research and knowledge provided by NATSPEC cannot be replaced by architects.

Fender Katsalidis Architects

NATSPEC creates many opportunities for manufacturers and specifiers to connect. It also offers many tools that generate demand, drive enquiries and motivate specifiers to actively engage Product Partners at different points in the lifecycle of a construction project.

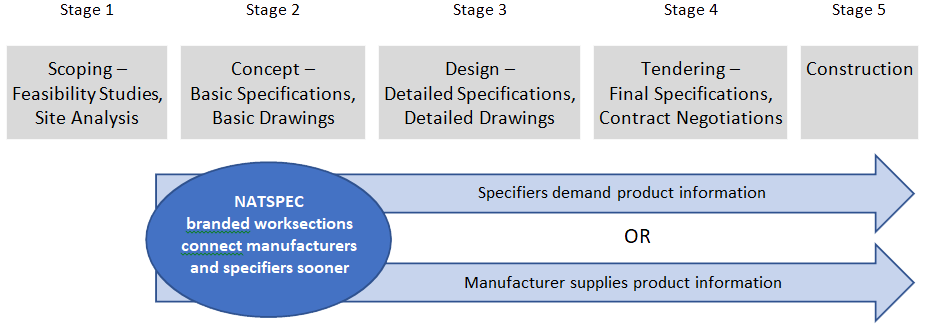

Construction Project Lifecycle

Figure 1

The NATSPEC branded worksection is one such tool, designed to assist manufacturers and specifiers to connect meaningfully, collaborate upfront and quickly build trust at an early stage (see Figure 1).

Each branded worksection is written by NATSPEC and a manufacturer to offer specifiers a pro-forma specification that is up to 90% pre-edited, compared to a generic worksection. This helps specifiers save significant time, reduce risk and gain more design control by minimising product substitution.

Manufacturers who have not used a branded worksection with their sales and marketing usually connect with specifiers during project-tendering (see Figure 1). When non-branded or generic sections have been used, it obviously opens up the possibility of competitive products to be selected if your product has not been specified. A specification may also be silent on substitutions making it easy for a builder to replace a product, previously specified at design stage, especially if doing so increases profit.

For detailed information about branded and generic worksections, please download:

TECHnote – GEN008 Branded versus Generic Worksections (Jul 08)

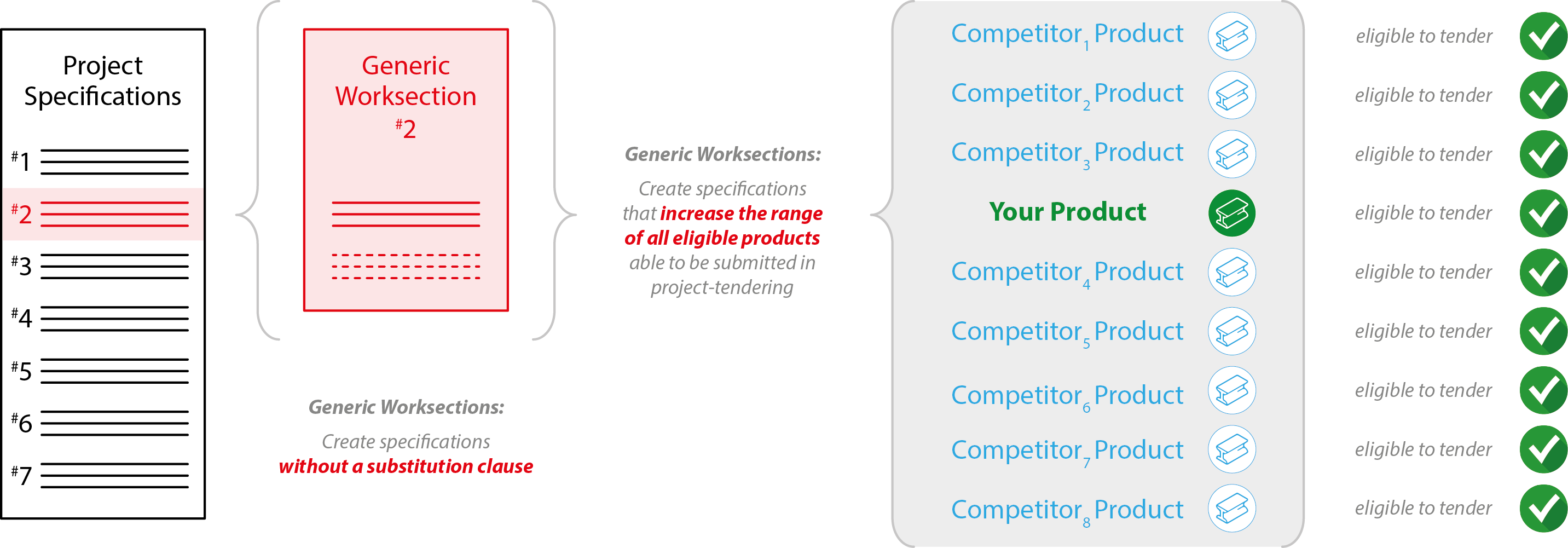

Specifications and Generic Worksections

Figure 2

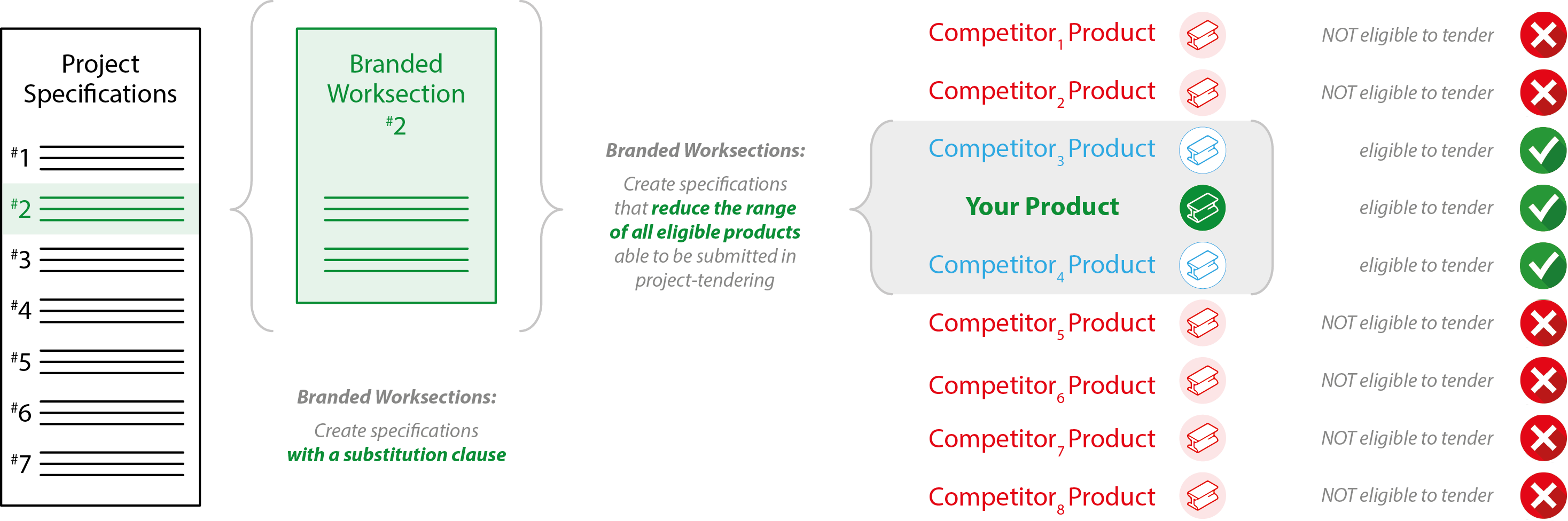

While the experiences depicted in Figure 2 are common for many manufacturers, they do not have to be. By comparison (see Figure 3), product partners who use a branded worksection to approach a specifier upfront during design phase can cut competition by the time of tender.

Specifications and Branded Worksections

Figure 3

Furthermore, unlike generic worksections, branded worksections also fight onsite substitution with a sub-clause that asks builders to satisfy key conditions before being allowed to change a product that is specified upfront.

For information about the substitution clause (as set out in sub-clause 2.1 of a branded worksection), please download:

TECHnote – GEN006 Product Specifying and Substitution (Oct 07 - Amdt Oct 15)

The benefits of using a branded worksection are clear.

NATSPEC Product Partners who use their branded worksection can:

- Reduce competition from other manufacturers and suppliers

- Fight substitution

- Get specified upfront

- Overcome claims

- Write better client briefs

- Increase brand awareness

- Improve client presentations

- Influence product selection

- Build trust and strengthen relations

- Cut risk from incorrect product specification

- Amplify marketing, promotions and trade exhibitions

DID YOU KNOW?

Manufacturers who wait until tender before trying to overturn a branded specification say it is much harder to substitute a competitor by then, compared to cutting them altogether out upfront (with a branded worksection) when the specification is written. This is supported by 61% of specifiers saying that more than 3/4 of the products they specify end up being used in a project.[1]

WANT TO GET SPECIFIED UPFRONT, REDUCE COMPETITION AND FIGHT SUBSTITUTION?

Use branded worksections.

Questions? Please contact: This email address is being protected from spambots. You need JavaScript enabled to view it.

[1]Source: Dodge Data & Analytics. May 2017. Exploding 9 Myths About Building Product Selection [ONLINE]. Available at: https://www.construction.com/toolkit/guides/Exploding-9-Myths [Accessed: 12 July 2018].